Tungsten Carbide Punch Used Environment

In engineering practice, tungsten carbide punch mainly work in multiple collision impact loads, the collision contact surfaces after a long impact, prone to various forms of damage, so fatigue becomes the most common failure of tungsten carbide punch. Tungsten carbide punch in the destruction process is repeated under the impact of crack initiation and propagation process is a kind of fatigue damage accumulation, multi-called impact fatigue or combat fatigue.

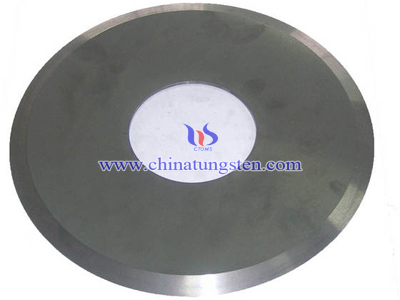

Tungsten carbide punch has high hardness, high wear resistance, high red hardness, etc. is known as modern dental industry, oil drilling, mining, metallurgy, machinery, chemical, military and other fields essential tool materials. Carbide is mainly used for the production of tungsten carbide punch nuts, screws, nails and other parts of the steel wall, their working conditions are under a certain load to bear one or more times in order to make the impact of processing forming metal parts reach the size requirements. In the actual working conditions, tungsten carbide punch vulnerable alternating load, shock, vibration effects, very poor conditions of service. Experienced the impact of millions of times, the carbide surface prone to micro-cracks, the cracks expand slowly in the ongoing work under, leading to mold failure.

Tungsten carbide punch advantage is the high material utilization, metal consumption, high production efficiency, resistance to high degree of automation. Punch in the work process to bear a huge impact, unit pressure up 200MPa, and therefore requires tungsten carbide punch has high hardness, high wear resistance, high impact strength and fatigue sufficient toughness.